- Home

- Products

-

Element

Non-metallic Materials

Non-metallic materials are used for a wide variety of applications in a range of industries, often as solutions where traditional metallic materials cannot be used. Non-metallic materials offer a range of physical and chemical properties, including having low thermal and electrical conductivity, making them good insulators as well as offering a high resistance to chemicals and corrosion. They can, however, be brittle and tend to have a low melting or boiling point. When applied with stress, non-metallic materials will often show an elastic, plastic, or viscous response.

View detailsHeavy Metal Material

Heavy metals are generally defined as metals with relatively high densities, atomic weights, or atomic numbers. The criteria used, and whether metalloids are included, vary depending on the author and context.

View detailsProject Quote

All technical aspects in the rectification process of user's equal protection construction are realized, and all levels of protection are realized to meet the requirements of the latest level of protection standards. Users only need one platform to manage all kinds of security functions, realize the layout of security topology, and make security operation and maintenance easier.

View details -

Technology and Service

Technology and ServiceExplore solutions and select the right one for your demands, including Metallurgy Casting,Refractory Paint,Conductive Material Application,Antifriction material Application

Non-Heavy Metal Material

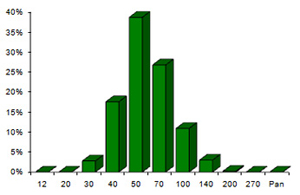

Special Service Professional Knowledge How to Choose grit size of Chromite Sand?

- About us

Who we are

Writing is a way and tool for human beings to record and express information with ideographic symbols, which has been handed down for a long time

View detailsQuality

Writing is a way and tool for human beings to record and express information with ideographic symbols, which has been handed down for a long time

View detailsCulture

Writing is a way and tool for human beings to record and express information with ideographic symbols, which has been handed down for a long time

View detailsTraining

Writing is a way and tool for human beings to record and express information with ideographic symbols, which has been handed down for a long time

View detailsContact Us

Writing is a way and tool for human beings to record and express information with ideographic symbols, which has been handed down for a long time

View details - News

- Download

- Contact us

Contact Us

Writing is a way and tool for human beings to record and express information with ideographic symbols, which has been handed down for a long time

View details